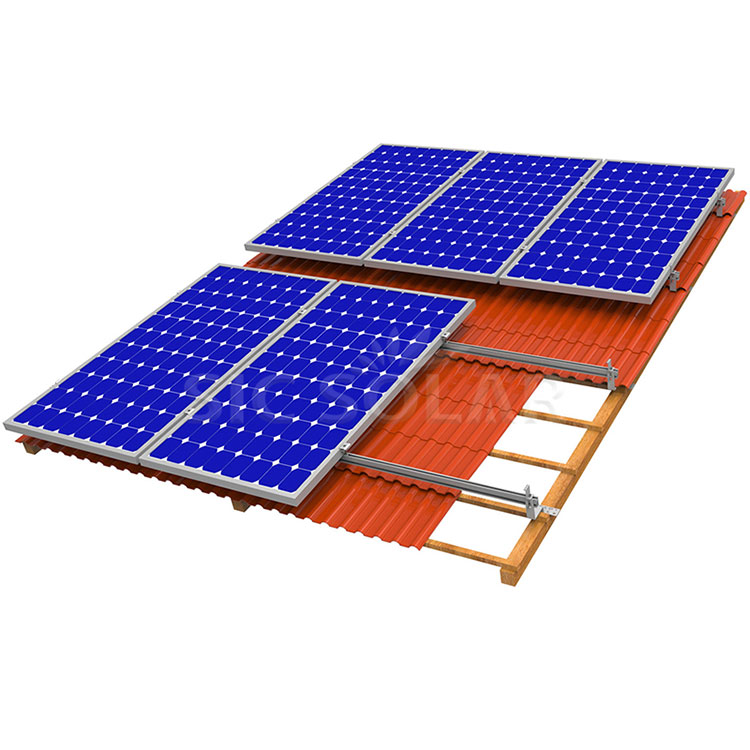

Upgrading a solar system to a tiled roof requires careful consideration. Choosing the wrong mounting system can lead to leaks, damage, or inadequate performance. Choosing the right mounting system involves many considerations. This guide will highlight key factors. Join SIC Solar as we explore the key selection criteria for Solar Roof Tiles.

Roof Tile Type and Shape: The specific tile shape, size, weight, and material (e.g., clay, concrete, slate, or composite) determine the required mounting system design.

Structural Integrity and Load Rating: System components must be selected based on the specific location and meet local wind, snow, and seismic load requirements to ensure normal operating conditions.

Waterproofing and Long-Term Protection: Solar Roof Tiles must maintain the roof's weatherproof integrity, preventing leaks for decades that could disrupt the entire solar system.

Installation Efficiency: Pre-assembled components and an intuitive design significantly reduce labor time and complexity.

System Lifespan and Warranty: Components must be corrosion-resistant and come with a reliable warranty.

Tile Type and Size: Understand the minimum/maximum tile length, width, and thickness that the system can accommodate.

Hook Design: Product material, hook profile, and connection method customized to the specific tile profile.

Flashing System: Solar Roof Tile requires consideration of an integrated sealing design and compatibility with the subfloor.

Material Composition:

Rail: 6005-T5 aluminum alloy (anodized to AA-M10-C22 or higher for enhanced corrosion resistance).

Clamp: 6005-T5 aluminum alloy or AISI 304/316 stainless steel.

Bolts and Nuts: Minimum AISI 304 stainless steel; AISI 316 is recommended for harsh coastal environments. Mechanical Strength:

Track Tensile Strength: ≥ 230 MPa

Track Yield Strength: ≥ 190 MPa

Load Rating:

Wind Load: Up to 60 m/s (216 km/h or 134 mph), depending on configuration and local standards (EN 1991-1-4, ASCE 7, AS/NZS 1170.2).

Snow Load: Typically 1.0 kN/m² to 1.5 kN/m² (approximately 100 kg/m² to 150 kg/m² or 20.9 psf to 31.4 psf), with higher loads available.

Rail Sections: Typically available in standard lengths, but can be easily cut on-site for custom requirements.

Installation Tilt: Adjustable tilt angle (typically 5° to over 35°) using a tilt bracket.

Roof Pitch Compatibility: Compatible with common Solar Roof Tile pitches (e.g., 15° to 60°).

Module Compatibility: Universally compatible with standard PV module frames (framed modules), with clamp profiles designed for a variety of module thicknesses.

| Feature Category | Product Specifications | Benefit |

| Primary Materials | Rails: Aluminum Alloy 6005-T5, Anodized (AA-M10-C22/AAMA 611) Hooks/Clamps: AISI 304 or 316 SS / Al Alloy | Exceptional strength-to-weight ratio, superior corrosion resistance for 25+ year lifespan. |

| Compatibility | Wide range: Concrete, Clay profiles (Roman, S, Mission), Slate. Custom hooks available. | Versatile solution for diverse global roofing styles. Minimizes project complexity. |

| Load Performance | Wind: Up to 60 m/s (Certified to EN 1990, AS/NZS 1170, JIS, ANSI) Snow: Configurable up to 1.5+ kN/m² | Engineered for safety in extreme weather, meeting rigorous international structural standards. |

| Waterproofing | Integrated flashing collar (Aluminum or SS), EPDM seals, compatible with most underlayments. | Guaranteed long-term weatherproof integrity, preventing leaks and roof damage. |

| Installation | Pre-assembled components, tool-less mid-clamps (options), lightweight rails, detailed manuals & videos. | Reduces installation time by 30%+, lowers labor costs, minimizes on-site errors. |

| Technical Compliance | Fully certified to CE, TUV SUD, ISO 9001:2015. Comprehensive test reports. | Global market access assured. Rigorous quality control from R&D to manufacturing. |

| Warranty | Product: 10 Years Limited Warranty Performance: 25-Year Structural Lifetime Commitment | Unmatched confidence in material quality and long-term system reliability. |